mars lander. international space station. JINKOSOLAR PANELS.

all protected by dupont™ tedlar® , the industry’s MOST LONG-LASTING AND DURABLE BACKSHEET FILM

DuPont Global Field Reliability Program

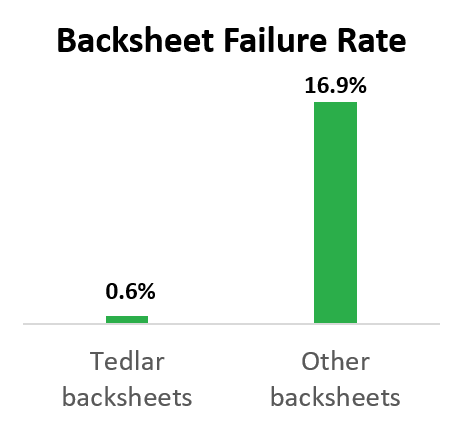

JinkoSolar has a strategic relationship with DuPont™️, the inventor of Kevlar, to incorporate its strong, durable Tedlar®️ material into its EAGLE Modules backsheets. Tedlar®️ is the only material proven to last more than 30 years in the field. Because backsheet failures represent a large problem in the field, many customers buy from JinkoSolar due to the proven materials used. Since 2011, DuPont™️ has been conducting worldwide field surveys to inspect, assess, and understand the state of degradation of PV modules with varying ages, bill of materials, and in a variety of geographies and climates all over the world. This survey included:

13m+

modules

630+

installations

4GW

Total Power

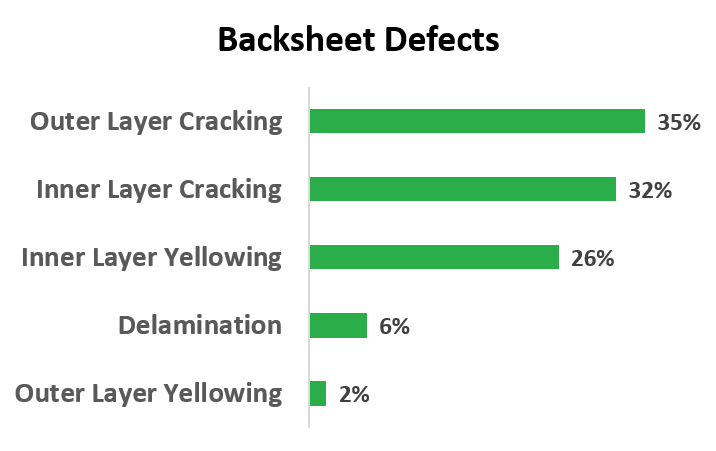

Typical Backsheet Field Failure Mode

pa backsheet

Backsheet Cracking

After 3-4 years

pvdf backsheet

Outer Layer Cracking

After 6-7 years

PET Backsheet

Inner Layer Cracking

After 3-4 years

PVDF Backsheet

Inner Layer Cracking

After 3-4 years

PET Backsheet

Bubbling, Delamination

After 6-7 years

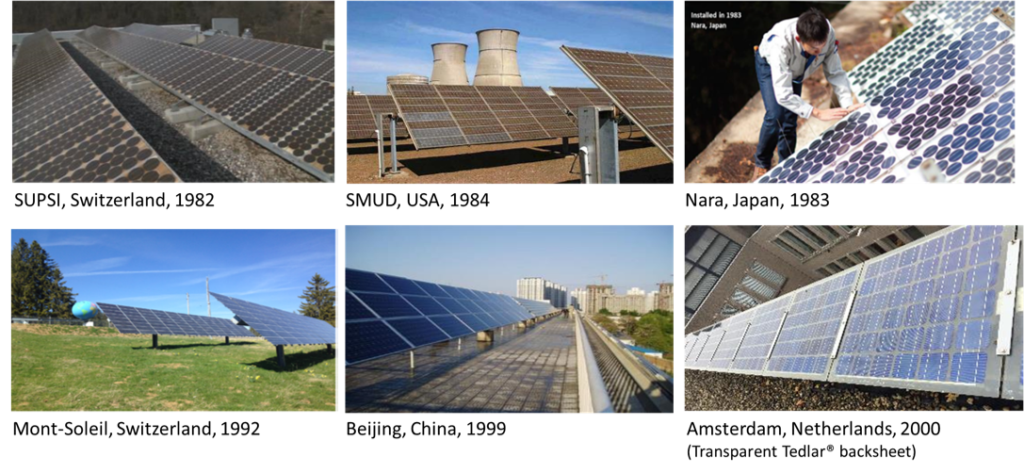

Field Proven Cases of Tedlar Backsheet

Glass + Backsheet Structure = 40+ Years Field Proven

Breathable backsheet allows moisture and gases from encapsulant degradation to be released out of module

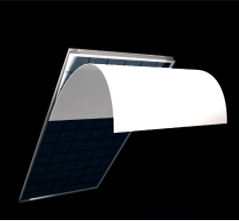

monofacial module

40yrs+ field proven record

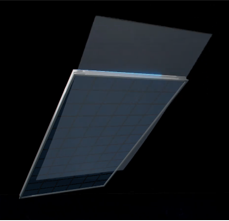

bifacial module

Same module structure

Same manufacturing process

Same BOS and installation

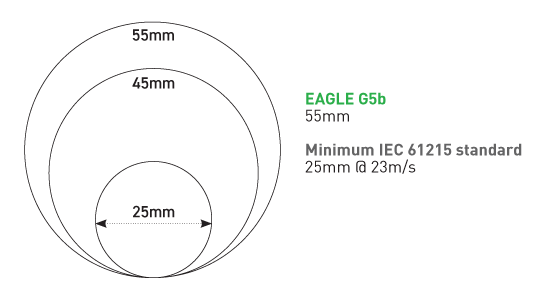

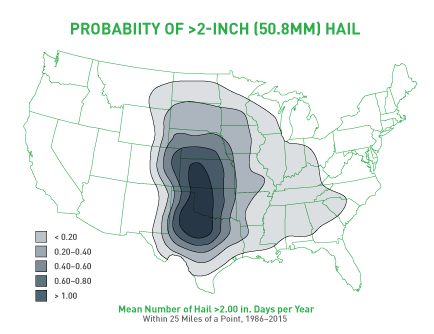

3.2mm Fully Tempered Glass = Better Hail Resistance

jinkosolar

3.2mm fully tempered glass

Hail resistance up to 55mm hailstone

other manufaturers

2.0mm Heat Strengthened Glass

Many 2.0 modules only pass up to 45mm hailstone resistance test,

while others have failed

Source: RETC

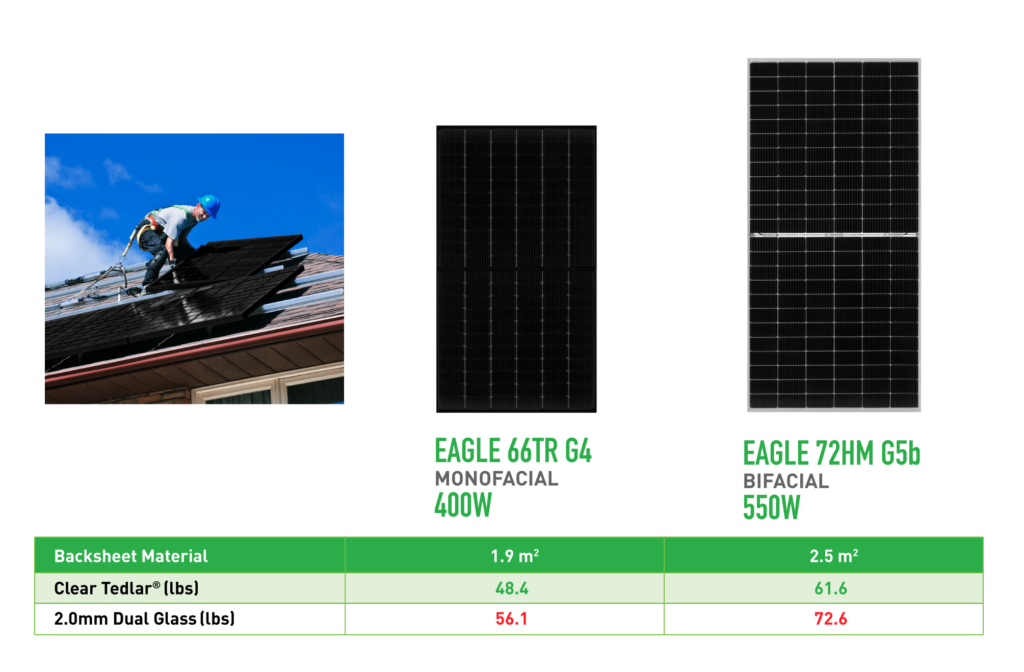

Light Weight Module = Easy Installation

*All information is based on 2021 DuPont™ Tedlar® Field Study